In today's fast-paced and competitive business world, it is a must for inventory businesses to be able to quickly turn around orders from the time the order is placed until the time the order is shipped out. Most highly successful businesses have this window set at less than 24 hours. In order to accomplish this, it is essential to have the proper software and a warehouse that is set up in the most efficient manner possible.

This not only ensures that orders are shipped out quickly but also helps to reduce shipping errors, which can increase costs and result in customer complaints. Proper planning of a warehouse's location setup, bin/shelf locations, barcode scanning, and order routing are some of the critical factors in achieving an efficient warehouse operation. Additionally, the use of warehouse management system (WMS) software can streamline warehouse operations and help businesses to manage their inventory more effectively.

Warehouse location setup planning

One of the first steps in setting up an efficient warehouse is to plan the location setup. This involves determining the most efficient layout for the warehouse, which includes the placement of bins and shelves, as well as the routing of orders through the warehouse. By planning the layout of the warehouse carefully, businesses can minimize the distance that products must travel from their storage location to the shipping area, reducing the time required to fulfill orders.

Bin/shelf locations

Once the layout of the warehouse has been planned, it is important to determine the most efficient locations for bins and shelves. This involves considering the type of product being stored, its size, and its weight. By organizing products in a logical manner and placing them in locations that are easily accessible, businesses can reduce the time required to pick products for shipping.

Barcoding and preventing shipping errors

Another critical factor in achieving an efficient warehouse operation is the use of barcoding and other technologies to prevent shipping errors. Barcoding technology can be used to track products as they move through the warehouse, from receipt to shipping. This allows businesses to quickly identify and correct any errors that may occur in the shipping process, reducing the likelihood of customer complaints and associated costs.

In addition to barcoding, businesses can also use other technologies to prevent shipping errors, such as pick-to-light systems, which guide employees to the correct location for picking products. These systems can significantly reduce the time required to pick products and can also help to prevent errors by ensuring that the correct products are selected for shipping.

Order routing

Order routing is another critical factor in achieving an efficient warehouse operation. By routing orders through the warehouse in a logical and efficient manner, businesses can minimize the time required to fulfill orders. This involves considering the most efficient routes for picking and shipping products, as well as the location of the products within the warehouse.

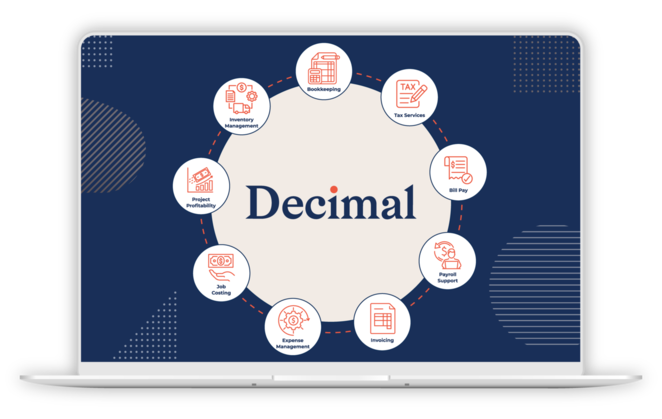

WMS software

Finally, the use of warehouse management system (WMS) software can help businesses to manage their inventory more effectively and streamline warehouse operations. WMS software provides businesses with real-time information about their inventory levels, order status, and shipping schedules. This information can be used to make more informed decisions about inventory management, order fulfillment, and shipping.

In addition to providing real-time information, WMS software can also automate many of the tasks involved in warehouse operations, such as inventory tracking and order routing. This can help businesses to reduce the time and resources required to manage their inventory and fulfill orders, resulting in a more efficient warehouse operation.

Wrapping up (no pun intended 🙂)

In today's fast-paced and competitive business world, having an efficient warehouse operation is a must. Proper planning of a warehouse's location setup, bin/shelf locations, barcode scanning, and order routing are all critical factors in achieving an efficient warehouse operation. Additionally, the use of WMS software can help businesses to manage their inventory more effectively and streamline warehouse operations. By implementing these best practices, businesses can ensure that their orders are shipped out quickly and accurately, reducing costs and improving customer satisfaction.

If you have additional questions about your client’s warehouse setup, proper inventory controls, or other warehouse-related issues. The Woodard Consulting Group would be happy to assist you. We even offer the option to go on-site with you and your client to consult on their warehouse setup, inventory control, accounting processes, and procedures, WMS set-up, and much more to improve their order turn times and overall efficiency.

Read the 1st article from this series on inventory management HERE.

.png?width=150&height=63&name=TWRlogo-regmark_blueblack%20(1).png)

.png)

Do you have questions about this article? Email us and let us know > info@woodard.com

Comments: