For any business that deals in physical products, inventory is one of the biggest factors that can impact its financial health and business at large. Having adequate inventory enables an organization to uphold its fulfillment commitments and stay in line with its customers’ expectations. On the one hand, a low inventory level could prevent it from manufacturing its products on time and ultimately delay shipping the orders. On the other hand, having more inventory in stock than needed can sabotage the cash flow and make the business vulnerable to losses caused by damages, theft, and being unable to store other items that can bring in revenue.

Every business should prepare a plan to fight different inventory risks to maintain the sustainability of operations. As an accounting professional, you have the expertise and opportunity to help clients understand and create an effective plan to help them mitigate these risks. In this article, we'll cover some of the major inventory risks that affect most sectors and business sizes, along with strategies to prevent them. Let’s get started.

What is meant by inventory risk?

Inventory risks are possible situations where an organization is unable to keep its operations in sync with its planning. Receiving stock ahead of schedule can lead to unforeseen inconveniences, requiring you to suddenly make space in your storage area and resulting in disorganized inventory. Moreover, it can disrupt your production plans and affect the timing of shipping other items. Facing delays in receiving inventory from suppliers can disrupt production and lead to costly alternative sourcing options. The underlying issue in both scenarios is the uncertainty surrounding inventory, which plays a crucial role in various aspects of business operations. Thus, the solution to most of the inventory risk types is to minimize the uncertainty and build robust inventory management techniques to safeguard your interests. Let us have a look at different types of inventory risks and how you can minimize their effects:

Types of inventory risks

Improper sales forecasting

When sales forecasts overestimate or underestimate the actual demand, you end up with disproportionate inventory levels. As mentioned earlier, having more inventory than necessary reduces your business’s financial health, while having less inventory jeopardizes your fulfillment commitments. The biggest results of inventory risks faced by improper sales forecasting include:

- Losing sales

- Frequent stock-outs

- Inflated procurement costs due to alternate sourcing

- Holding excess stocks

- Adverse impact on cash flow management

Supplier bottlenecks

Supplier-side bottlenecks are equally common. Receiving your stock on time is crucial to avoid the risks of having too much or too little inventory. When suppliers consistently fail to meet delivery deadlines, it adds unnecessary pressure to your production and sales channels. Suppose you are fully dependent on a single vendor or supplier for a particular item. In that case, it is necessary to mitigate such risks with the help of SLAs (service level agreements) and clearly defined deliverables. Also, decide the accountability for all parties, including your logistics partners, in order to streamline the overall supply chain.

Storing perishable goods

If your business stores goods that are perishable in nature, it poses additional risks that are associated with the inventory carrying costs. No doubt you will have to employ additional resources to maintain their storing conditions, but at the same time, their consumption rate needs to be checked. If you use them at a higher rate, the lead time could halt your production line, while slow consumption will result in them becoming unfit for use.

The best way to manage risks associated with perishable goods is to maintain a steady production flow with adequate cushioning by ensuring instant availability if they go out of stock. On the other hand, you may want to pool such items with other businesses that are not your direct competitors so they can absorb the excess stock if required. In case that’s not possible, you can always increase the production rate and direct your sales channels to send additional finished goods into the market as per their marketing strategy.

Damaged inventory

In many cases, the stored items get damaged due to mishandling during storage or due to bad storage conditions. For instance, placing items on store shelves that are stained with oil can damage items like clothing. On the other hand, faulty retrieval can also harm the fitness of an item for production. This is a serious challenge for any business as your staff members will only get to know about the issue right before production/assembly. Accidents and natural calamities can also cause damaged inventory.

Theft and loss of inventory items

Theft is a common problem with large storage facilities that lack adequate monitoring. ABC analysis can be considered an effective way of minimizing theft as it allows you to focus on more precious items that need less effort to count. On the other hand, you may also face miscellaneous loss of inventory items, and most businesses do need to write off a certain part of their inventory as losses. This area can be approached only by overall refinement of your inventory management practices, tools used, and proper staff training.

Product lifecycle-based concerns

For many businesses, the decreasing product life cycles are becoming a major source of inventory risks. The bullwhip effect can be considered one of its common reactions as many suppliers would reduce/increase the production of their products depending on market speculations. For instance, if an OEM (original equipment manufacturer) feels that a certain automobile company will discontinue a vehicle, they might cut down or even stop the production of the parts they manufacture without acknowledging the same with their client. This also goes the other way around, and the best way to reduce such risks is by improving communication. You can also create separate provisions like giving notice before stopping procurement and ensuring that you pay your vendors on mutually agreed terms.

How To Reduce Inventory Risks Caused By These Issues

Firstly improve your sales forecasts and take the help of advanced BI tools wherever needed. You should also integrate your inventory management software with your e-commerce store’s front-end and POS systems. This will give you a better idea of the sales trends and provide you with real-time insights into sales trends. You can also modernize your material handling system and upgrade your storage facility to meet inventory visibility goals. This can be in the form of installing various sensors or even implementing an AS/RS package. This way, you can swiftly analyze the popular products, related SKUs, current inventory levels, lead times, and a lot of other important metrics.

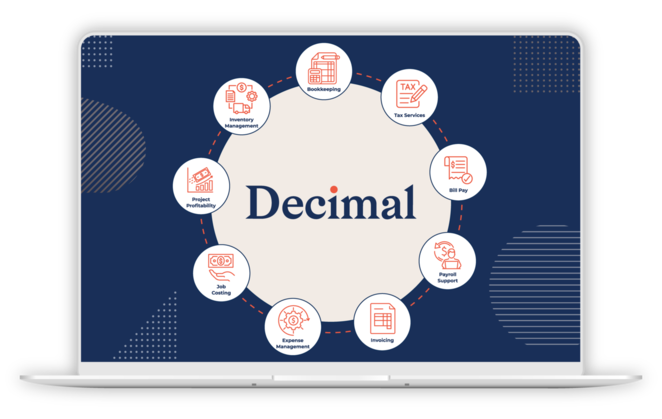

Your success in minimizing inventory risks depends on how transparent your supply chain is and how well you respond to the changes in demand. It will require you to maintain the bidirectional flow of data with both your suppliers and sales channels with appropriate measures to safeguard your business interests. A large portion of your inventory risk mitigation depends on your technical stack. Check out the best inventory management software solutions available on the market today to get a leg up on addressing the inventory risks we covered above.

Sponsored Content: This article is generously brought to you by one of our valued sponsors. Their support enables us to continue delivering expert insights and the latest industry trends to our dedicated community of accounting professionals.

.png?width=150&height=63&name=TWRlogo-regmark_blueblack%20(1).png)

.png)

Do you have questions about this article? Email us and let us know > info@woodard.com

Comments: