A container ship stuck in the Suez Canal prompted the last article on supply chain disruptions. Yesterday, the United States woke up to news of a state of emergency after a ransomware cyber attack forced Colonial Pipeline to take all systems offline on Friday. The emergency legislation waived rules on fuel transported by road - a move considered necessary to mitigate the loss of 45% of the supply of diesel, gasoline and jet fuel that is typically moved through Colonials 5,500 miles of fuel pipelines.

Supply chains that have already been stretched thin since the start of the pandemic will continue to struggle. Well before the weekend news about Colonial, many news outlets had begun reporting at the end of April that a shortage of truck drivers would be affecting deliveries in both the near and the short term. With the National Tank Truck Carriers announcing that 25 percent of tank trucks are already parked heading into this summer because of a lack of qualified drivers, the need to transport fuel supplies by road for even a short period of time will cause a ripple effect in supply chains.

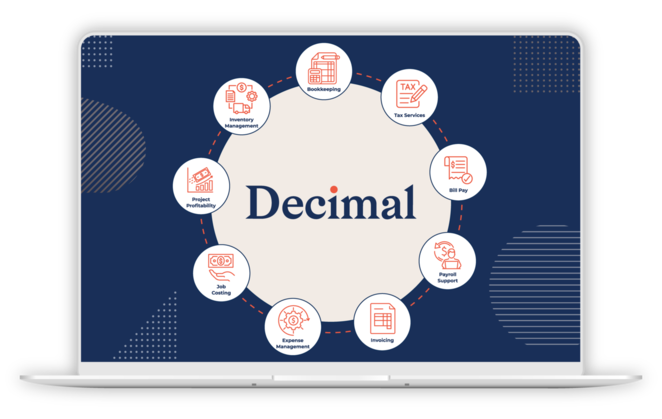

What does this mean for you - an accountant or bookkeeper? The information below comes from a conversation between Joe Woodard and Tom Uva.

Supply chains are not just for manufacturers.

You may not need to purchase much for your practice to run, but we are willing to bet that at least one (or most if not all) of your clients either buys or sells stuff either as a core piece of their business or to enable them to conduct their business. Without the movement of goods, their businesses just won't function. With insight into their accounting and business processes, you are in a unique position to help them face this continuing disruption.

Ask questions to manage risk.

The best thing you can do for your clients is to ask them questions. Start with a simple, "Are you having trouble getting in the things you need to do business?" Then, get them thinking about the full supply chain involved. Are there alternatives to direct suppliers (tier one suppliers)? Have those suppliers created a plan for alternative sources for their suppliers (tier two)? Have they built contingency plans in the event they only receive partial shipments? Do contracts have negotiated language on failure to deliver?

Communications are vital both upstream and downstream.

Communication is vital. Have your clients created a communication plan for both customers and suppliers?

At the Customer Level. Businesses need to establish a regular communication cadence with their customers. Customers should hear proactively on potential issues, existing issues and issue resolution. Advise your clients to align with their customers on supply and demand assumptions regularly and avoid wide swings in messaging.

When unable to meet a customer order, your clients should provide a timely explanation to customers and communicate clearly how the situation may be resolved. If possible, include information about changing the order to alternative products.

If necessary, production changes may need to be made. Your clients should understand what products customers need asap and prioritize production or delivery of those items over things customers can live without. However, they must also be aware of all contractual obligations, including priority.

At the Business Level. Have your clients created inter-company communication plans? Businesses need to have a thorough understanding of current raw material on hand as well as work-in-progress and finished goods or to have an accurate inventory of goods used to deliver services. It may be necessary to bring in technical experts to present options in terms of specification adjustments, alternate materials, etc. To facilitate decision making, some of this modeling may need to be done less elegantly, such as using Excel spreadsheets. Finally, if supply chain issues lead to cash flow issues, your clients may need to make decisions around AP and AR may need to be made. Structure around these decisions should be built before the situation arises.

At the Tier One Supplier Level. Just as with customers, it is essential to create a regular communication cadence with suppliers. Do not assume that your clients' suppliers will proactively contact your clients to let them know about potential issues. Instead, advise your clients to initiate communication and schedule regular update meetings. By establishing set intervals for communication, your clients will not be surprised or shocked by large swings in supply.

If possible, your clients should develop relationships with alternative tier one suppliers, even if just to order very small quantities to start. This redundancy may provide protection.

At the Tier Two Supplier Level. It is essential that your clients' suppliers have created a risk management plan with their own suppliers. Again, your clients should not assume that their suppliers have done this, so your clients should initiate a conversation and request regular status updates from their tier one suppliers about the status of their tier two suppliers. Your clients can leverage their own relationships with their tier one suppliers to reach out to tier two suppliers, but should use this only sparingly to emphasize and prioritize the clients' needs.

Managing supply chain risk means weighing trade-offs.

Here are some of the trade-offs businesses probably have already been considering and may continue to consider.

- low working capital targets vs. holding buffer of critical raw inputs

- lowest possible cost vs. total cost of ownership (+tariffs, freight, cost of poor quality, etc.)

- sourcing only in "low cost" region vs. alternative sites

- achieve scale with suppliers via spend aggregation vs. dual sourcing of critical, high-risk components

- low procurement overhead vs. resources to manage a multi-tier supply chain

- buying from only distributors vs. investing in vendor relationships

These trade-offs balance between leaner procurement model and a more strategic model.

What does this mean for you - an accountant or bookkeeper?

Your clients may have already optimized their supply chain and created risk management plans to survive the ongoing disruptions. But some of them probably have not. By starting a conversation with each of your clients, you may help someone save their business. And you may create a new engagement for yourself from that conversation.

So, here is a task for you to do this week. Email all clients: - Subject: Supply Chain Issues?

.png?width=150&height=63&name=TWRlogo-regmark_blueblack%20(1).png)

.png)

Do you have questions about this article? Email us and let us know > info@woodard.com

Comments: